Plug Flow Reactor Solved Problems Pdf

Stirred batch reactors example 1: 3.if there is zero conversion at the entry to the pfr and 60% at the exit;

2

The conversion of many reactions of interest is thermodynamically limited, that is, the reactions proceed also in the opposite direction and convert

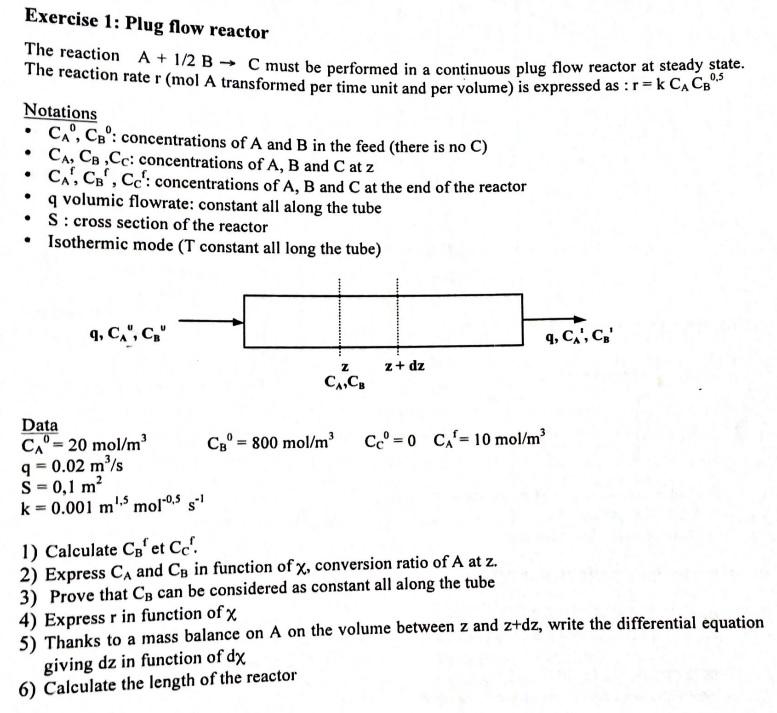

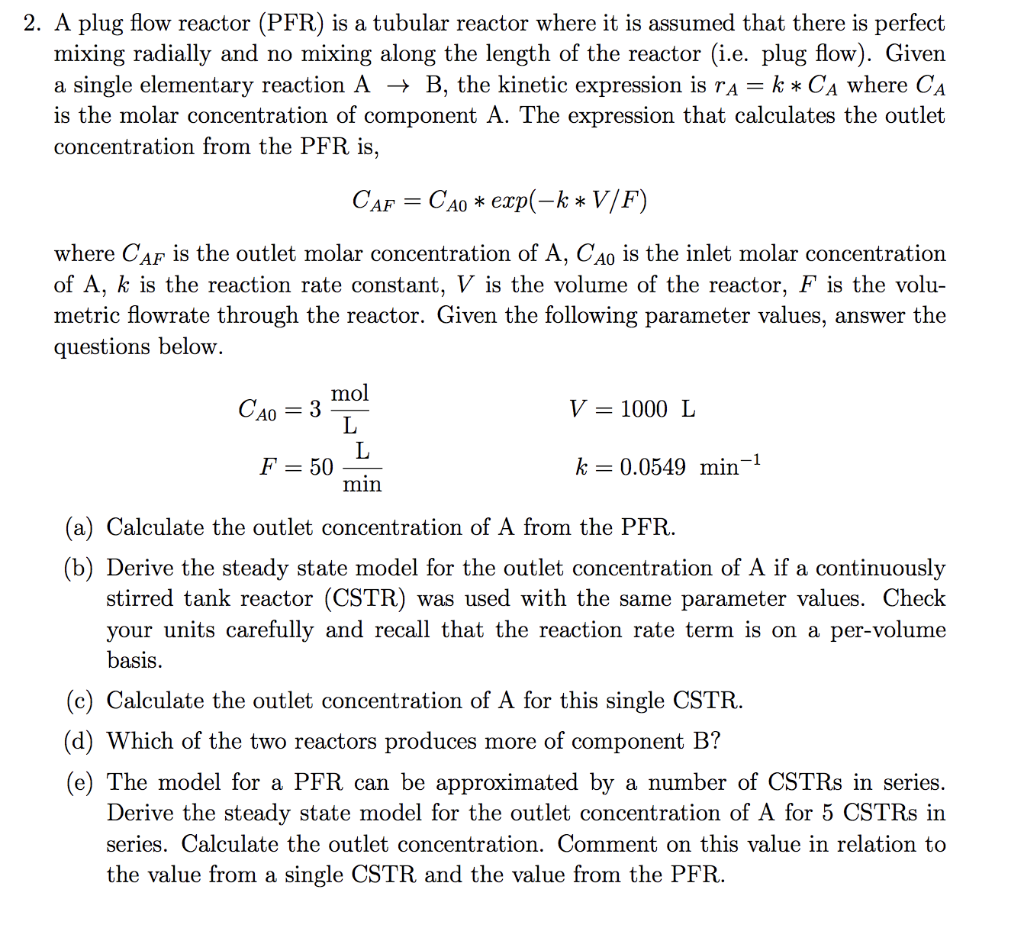

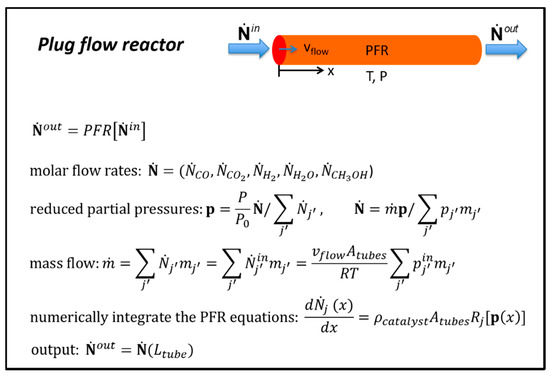

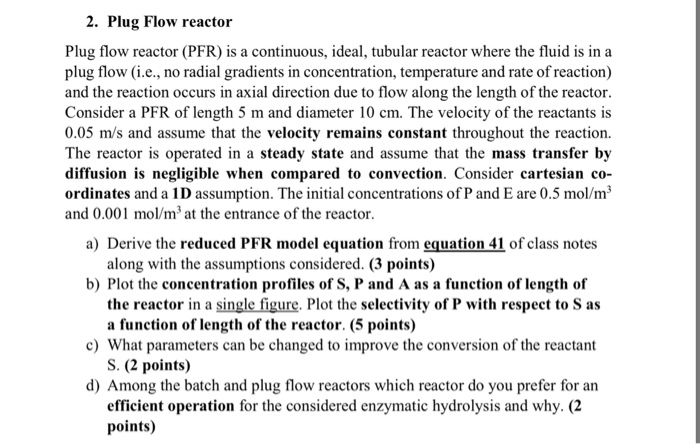

Plug flow reactor solved problems pdf. I) perfect instantaneous mixing perpendicular to flow, ii) no mixing in direction of flow this implies piston like flow with the reaction rate and concentration that vary along reactor fa o c a o fa =fa o (1−xa) ca fa o dxa=−()ra dv +a + =()) = F a= f a0 (1 x) liquid(constantflowrate) a. Equimolar amounts of chlorine and benzene at 70 oc and 2 bar are fed to an rstoic reactor in which 80% conversion of benzene is achieved.

Plug flow reactor (pfr) the third general type of reactor is the plug flow reactor (pfr). Reactor volume and flow path length, l, such that x l < 10 3 cells/100 ml 2. Debasree ghosh, lecture notes on polymer reaction engineering, module ii:

The reactor itself may consist of an empty Plug flow reactors (pfrs) another type of reactor used in industrial processes is the plug flow reactor (pfr). The stoichiometry of the reaction is 2a → r + s.

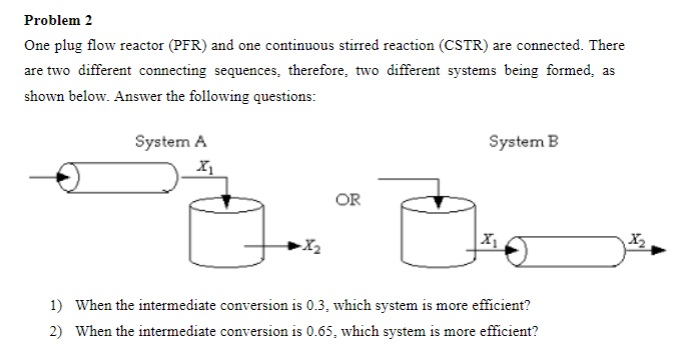

Like the cstrs, a constant flow of reactants and products and exit the reactor. Clearly state all assumptions used in your derivation. W is the mass of catalyst (grams);

The main aim is to solve practical examples and to demonstrate a systematic approach to solve engineering problems. One design may have low reactor cost, but the materials leaving the unit. Chemical reaction engineering (cre) deals with the design of chemical reactors to produce chemicals.

2.assuming these assumptions are all met, calculate the plug flow reactor’s volume to achieve a 60% conversion given a feed rate of 15mol.s 1 to the reactor. V= v 0 (1 + x) p 0 p t t 0 b. Solve problems in chemical reactor design.

The concentration of species and the temperature inside the pfr can vary with time (t), axial position (z),. Reactor at the new operating conditions of temperature and flow rate. The document is not exhaustive and contains only a brief introduction to the material and energy balance in chemical reactors.

Since the concentration varies continuously down the reactor tube, so does the reaction And ch4,0 c is the initial 2) based on the following data and assumptions:

The rates of chemical reactions leading to desired products are often too low to establish economically attractive processes. C a= c a0 (1 x) idealgas(variableflowrate) a. In searching for the optimum it is not just the cost of the reactor that must be minimized.

Calculate the flow of cooling water and the time needed to reach a conversion degree of 85%. V = v 0 (1 + x) p 0 p t t 0 b. In pfrs, however, the reactor contents are not continuously stirred.

C a= c a0 (1 x) (1 + x) p p 0 t 0 t (b) batch i. Chlorine concentration which must be added to insure that there is detectable chlorine at pfr exit (detection level = c l = 0.05 mg/l) 1. (multiple steady states) part i:

C a= c a0 (1 x) (1 + x) p p 0 t 0 t liquidorgas(constantvolume) a. Chemical reactor is known as the heart of any chemical plant since the new chemicals are produced only in this vessel and the economics of the entire plant depends on the design of reactor. These types of reactors are useful for fast reactions that could not be as easily observed in a batch environment.

Design of the reactor is no routine matter, and many alternatives can be proposed for a process. X is the conversion of methane; Rtd data + model + kinetics = prediction conflicting goals a model must • fit the data • be able to extrapolate theory and experiment

V = v 0 andc a= c a0 (1 x). Success or failure of n chemical plant. C a= f a v ii.

A plug flow reactor (pfr) is a pipe. Suffi ciently solved problems are: The source code (matlab, octave, excel or fortran) for many

The results form gives information about the outlet stream conditions and heat duty of the reactor, phase equilibrium, heat of reactions (if selected). 2.2.2 plug flow reactor (pfr) the main assumptions of the plug flow reactor are: Calculate the size of the plug flow reactor, operating at 100°c and 1

The reactor is filled in 10 minutes and emptied in 12 minutes. The system may be either contained (as in a water main, oil pipeline, or blood vessel) or open (as in a. If, for example the excel files open in internet explorer rather than in excel, you can configure internet explorer to open files directly in excel.

Instead, chemical species are flowed along a tube as a plug, as shown in figure 25.2. The design of chemical reactors is based on a few. Water is run through the reactor at a flow rate q(m 3/sec ) and t=0 the reactant a is added to the input stream on a continuous basis.

C a= n a v andn a= n a0 (1 x) idealgas(variablevolume) a. In a plug flow reactor, nutrients (and sometimes organisms) are introduced to the reactor continuously and move through the reactor as a “plug”. No pressure drop and no temperature changes occur.

Reactants are fed in one end of the pipe and some mixture of reactants and products emerge from the far end.

2 A Plug Flow Reactor Pfr Is A Tubular Reactor Cheggcom

2

Pdf A Plug Flow Reactor For Studying Fuel Autoignition Chemistry At Pressures Of Up To 50 Bar

Ode Solver For Pfr Pdf Ordinary Differential Equation Equations

Solved Problem 2 One Plug Flow Reactor Pfr And One Cheggcom

How To Solve Reactor Design Problems - Youtube

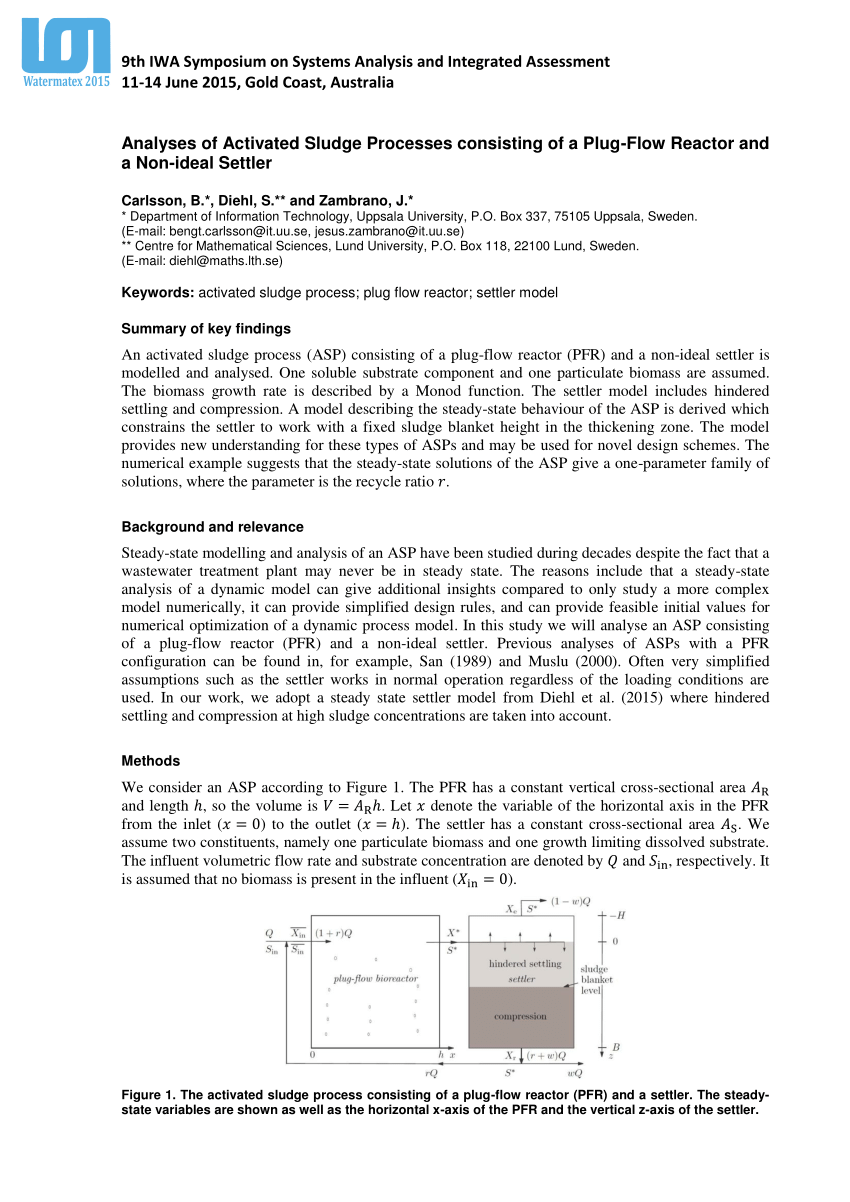

Pdf Analyses Of Activated Sludge Processes Consisting Of A Plug-flow Reactor And A Non-ideal Settler

Plug Flow Reactors Pfrs

Plug Flow Reactor Model - Wikipedia

Thoughts On Problem Solving Pfrcstr Example

Solved - 4 You Are Designing A Reactor That Uses Chlorine In A Pfr Or Cstr - 1 Answer Transtutors

2

Mass And Energy Balances

Matlab In Chemical Engineering At Cmu

Isothermal Plug Flow Reactor Part 1 - Youtube

Exercise 1 Plug Flow Reactor The Reaction A 12 B Cheggcom

Chemengineering Free Full-text Understanding Catalysisa Simplified Simulation Of Catalytic Reactors For Co2 Reduction Html

2 Plug Flow Reactor Plug Flow Reactor Pfr Is A Cheggcom

2